Eroding

Your partner for manufacturing. Simple processes, high quality, on-time delivery and attractive prices thanks to digital processes. Order components easily online.

1.500+

Satisfied customers

5.500+

Available machines

0,11%

Complaint rate

Audited suppliers

Global network with over 500 audited suppliers

Attractive prices

Highest quality and competitive prices for all manufacturing processes

Fast delivery

With Robtrix you reduce your delivery time by up to 50%

Wide range of materials

All plastics and metals available in over 600 materials

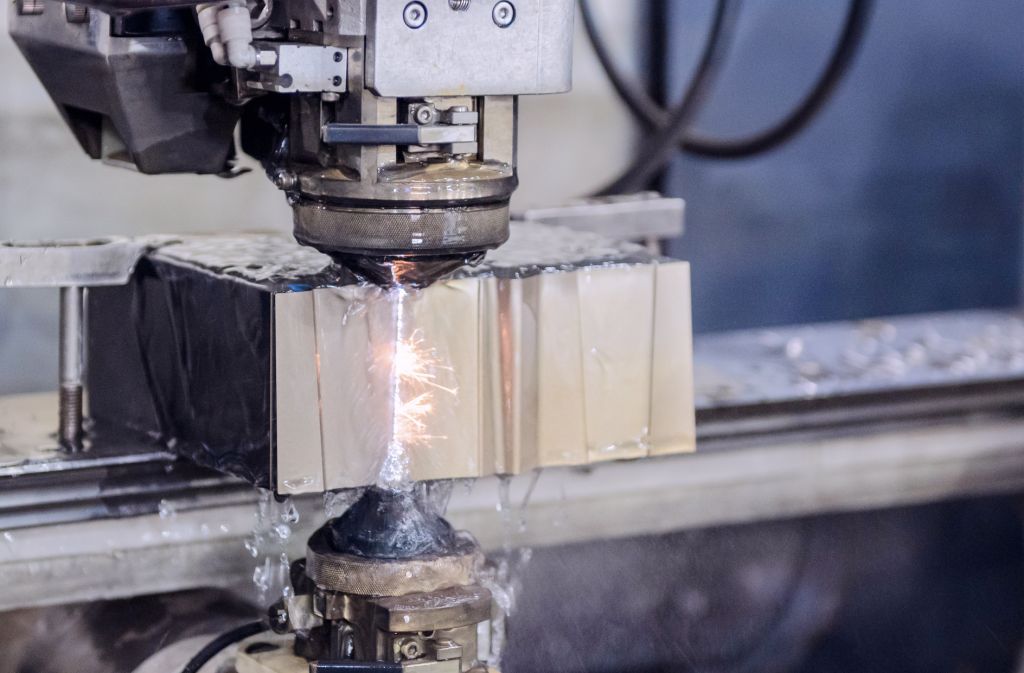

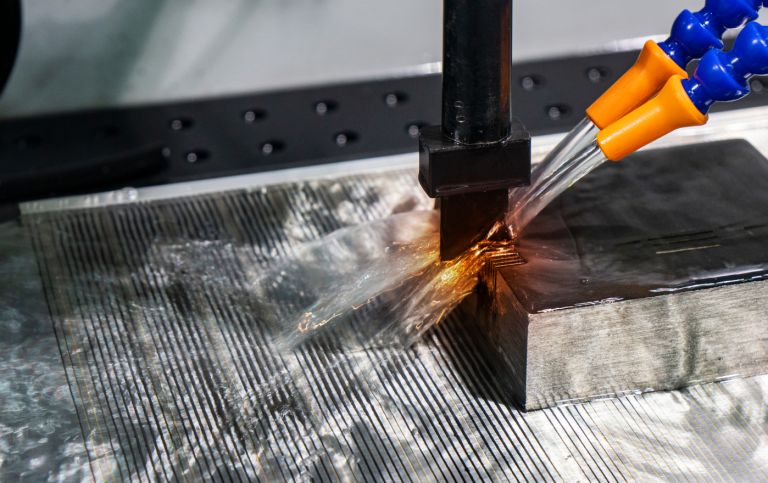

When it has to be particularly precise

Eroding for workpieces with the highest precision

Using modern CNC-controlled eroding machines, even extremely hard materials such as titanium and hardened steel can be precisely machined, where other machining processes reach their limits. Due to the high precision during eroding, components with filigree contours and complex geometries and bores are possible.

At Robtrix you can access a wide range of wire and die sinking EDM with up to 5 axes.

Eroding

Technical data

| Traverse paths: | X-axis up to 750 mm Y-axis up to 500 mm Z-axis up to 500 mm |

| Material thickness | up to 500 mm |

| Surface roughness: | up to Ra 0.8 / Rz3.2 |

| Tolerances: | up to +/- 0.005 mm |

| Ideal batch sizes: | 1 – 50.000 pieces |

Our materials

Available materials

| Aluminum | Copper |

| Bronze | Brass |

| Stainless steel | Titanium |

| Steel | other materials on request |

| Inconel |

Briefly explained

How does eroding work?

Eroding is a machining method in which material is removed by means of electricity. A distinction is made between the two processes of wire-cut eroding and die-sinking eroding. In principle, any current-conducting metal such as aluminum, steel, copper, brass or iron can be machined.

In eroding, an electrode is moved to the workpiece at a small distance without touching it. Within the narrow gap between the object to be machined and the electrode, an electric current flows that generates extremely high temperatures between 8,000 and 12,000 degrees Celsius. This results in material removal by discharge via sparks.

How much material is removed depends on the polarity, gap width, duration and intensity of machining, and other factors. Eroding as a machining technique is mainly used where highest precision and particularly tight tolerances are required.

Why Robtrix

Your advantages

- Flexible and free capacities at any time

- Attractive prices for all components

- Quality control according to ISO 9001:2015

- One contract and contact person for all manufacturing processes

- Digital processes with personal contact person

- Global Supply Chain with German Quality Standards 🇩🇪

You have the choice

Our delivery times

- Offer within 48 hours

- Standard production in 15-20 working days

- Express service in 6-12 working days

Surface treatment

We get the best out of your components

Refinement, appearance, protection against wear and corrosion prophylaxis of the turned components are as much part of our core business as the production of components.

- ✔ Sandblasting

- ✔ Paint

- ✔ Anodizing

- ✔ Powder coating

- ✔ Electroless nickel

- ✔ Galvanizing

- ✔ Passivate

- ✔ Chromate