Die casting

Your partner for die casting production and mold making at attractive prices. Material selection: Aluminum magnesium, brass, zinc and silicon tombac available. Upload CAD file and receive quote within 48 hours

1.500+

Satisfied customers

5.500+

Available machines

0,11%

Complaint rate

Audited suppliers

Global network with over 500 audited suppliers

Attractive prices

Highest quality and competitive prices for all manufacturing processes

Fast delivery

With Robtrix you reduce your delivery time by up to 50%

Wide range of materials

All plastics and metals available in over 600 materials

Simple processes for series production

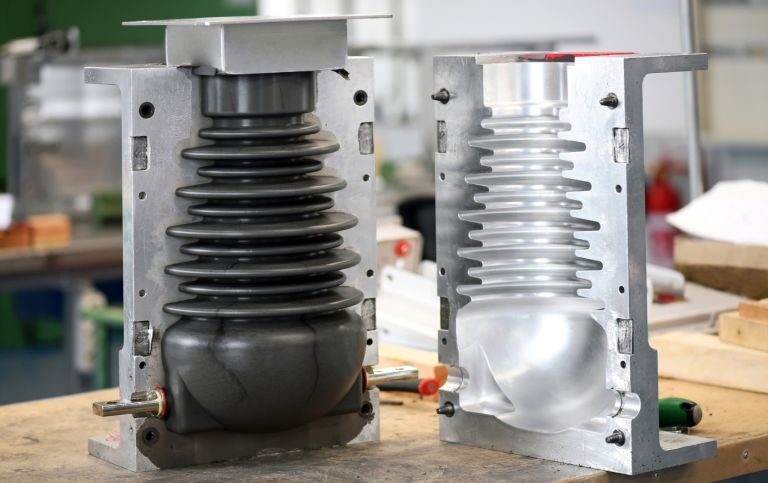

Cost-effective series production in die casting

Fully automated die casting ensures high cost-effectiveness and flexibility in series production and mass production. Robtrix offers a wide range of metals such as aluminum, zinc, magnesium in different alloys. We rely on state-of-the-art die casting processes with high dimensional accuracy and low tolerances.

Our offer includes die casting in hot chamber and cold chamber processes. In addition, we offer a wide range of surface finishing options. Robtrix is your partner for modern die casting production with simple processes along the entire supply chain.

Die casting

Technical data

| Material thickness: | 1 – 12 mm |

| Casting size | from 3 x 2 x 2 mm up to 1.500 x 1.500 x 6 mm |

| Casting weight | from 1g to 12 kg |

| Tolerances: | from 0,05 mm |

| Closing force: | 80 – 2000 T |

| Die casting tools: | Multiple cavities |

| Ideal batch sizes: | from 1.000 piece |

Our materials

Available materials

| Aluminum |

| Magnesium |

| Brass |

| Zinc |

| Silicon Tombac |

Zinc and magnesium

Hot chamber process

The hot chamber process is the most widely used die casting process. In this process, the casting vessel is immersed directly in the molten metal. The molten metal is forced into the die through a swan-neck-shaped pouring nozzle. The hot chamber process is used for metals with a low melting point, such as zinc and magnesium alloys.

Briefly explained

How does die casting manufacturing work

In the series production of comparatively complex metal parts, the die casting process is considered the manufacturing process of first choice.

Liquid metal is pressed under high hydraulic or pneumatic pressure into permanent molds (cavities) made of stainless steel. Due to their comparatively low melting point, aluminum, zinc and magnesium are among the most important materials for die casting.

Aluminum

Cold chamber process

The cold chamber process is used for alloys with a higher melting point. In this case, the casting set is located outside the metallic melt. The material is fed from an external melt pot directly to the injection cover, where a hydraulic piston injects the metal into the mold. The cold chamber process is mainly used in aluminum die casting.

Surface treatment

We get the best out of your components

Refinement, appearance, protection against wear and corrosion prophylaxis of the turned components are as much part of our core business as the production of components.

- ✔ Sandblasting

- ✔ Paint

- ✔ Anodizing

- ✔ Powder coating

- ✔ Electroless nickel

- ✔ Galvanizing

- ✔ Passivate

- ✔ Chromate