Injection molding

Your partner for injection molding incl. Mold making at attractive prices. Wide range of materials and fast delivery. Upload CAD file and receive quote within 48 hours.

1.500+

Satisfied customers

5.500+

Available machines

0,11%

Complaint rate

Audited suppliers

Global network with over 500 audited suppliers

Attractive prices

Highest quality and competitive prices for all manufacturing processes

Fast delivery

With Robtrix you reduce your delivery time by up to 50%

Wide range of materials

All plastics and metals available in over 600 materials

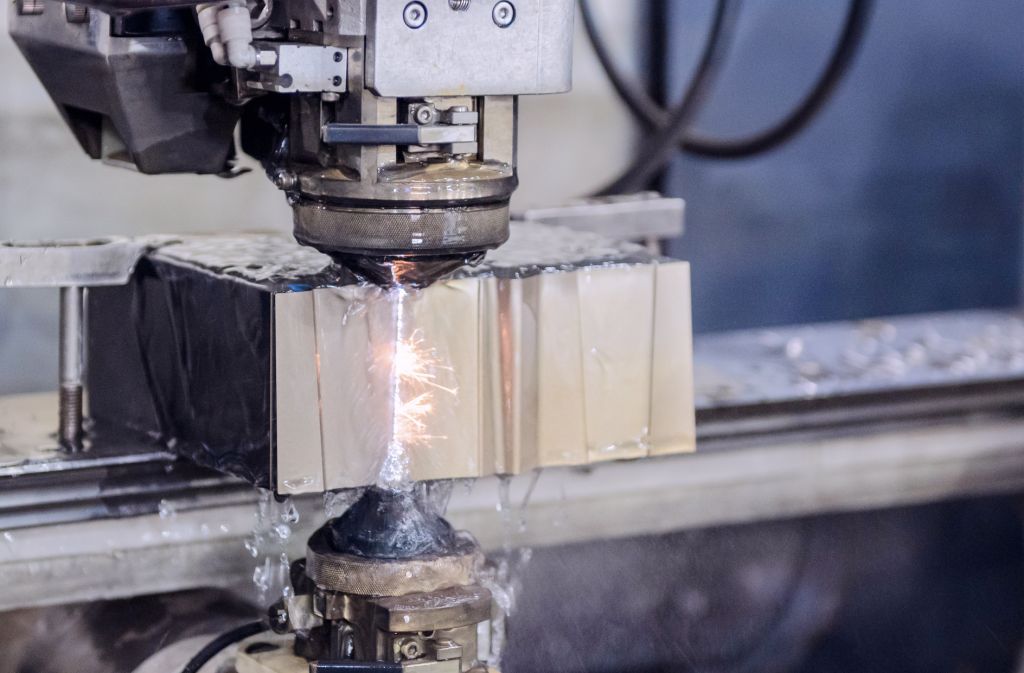

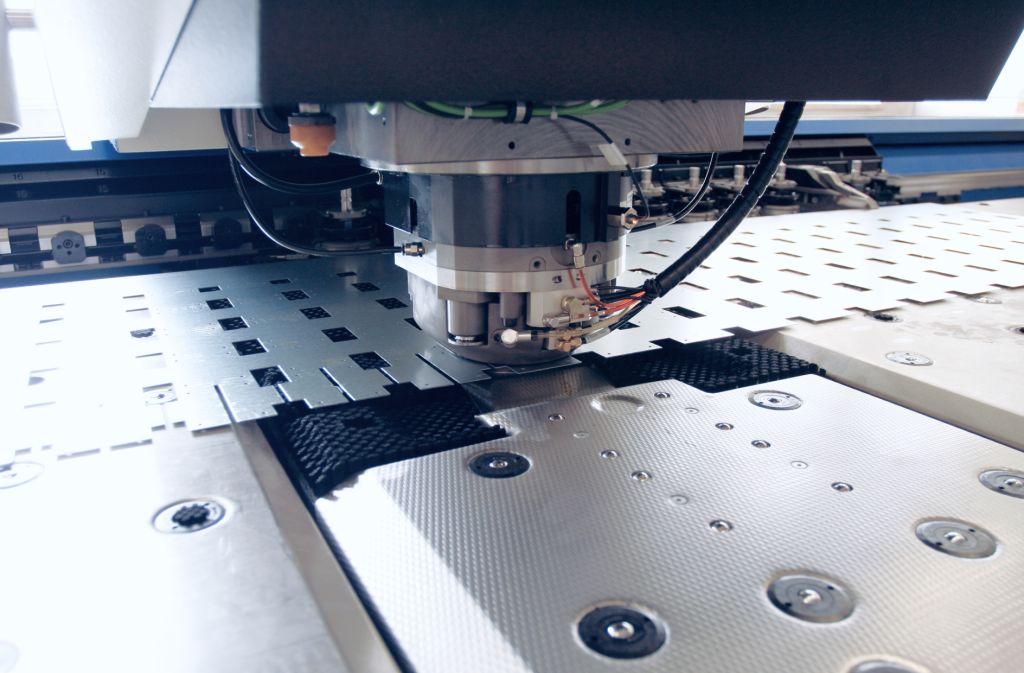

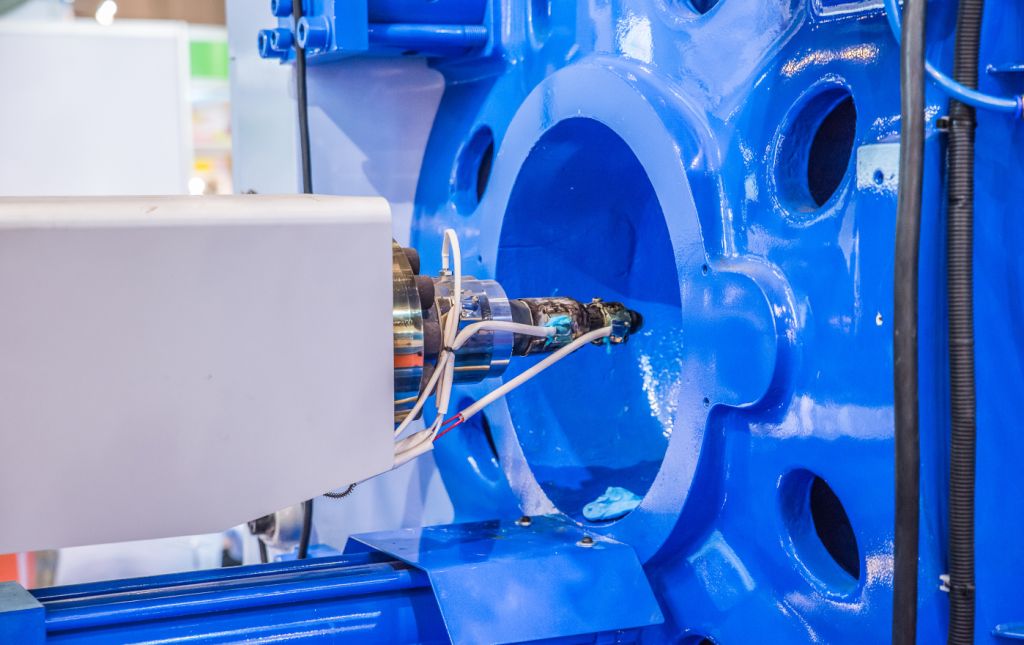

Modern series production

Cost-effective series production using injection molding

Injection molding is the manufacturing process of choice for the cost-effective production of small and large series. Robtrix offers a wide range of plastics and resins with the suitable strength and surface quality for your components.

These can also be provided with special surface finishes, polishing, engraving or surface structures. Thanks to our digital workflows, we can realize molded parts in injection molding in short lead times.

Injection molding

Technical data

| Material thickness: | 0.3 mm – 12 mm | |

| Dimensions: | min: 3 x 1 x 0.8 mm max: 1.500 x 1.500 x 6 mm |

|

| Component weight: | up to 15 Kg | |

| Tolerances: | up to 0,05 mm | |

| Closing force: | 20 – 2.500 T | |

| Ideal batch sizes: | from 100 piece | |

| Tools: | Single cavities Multiple cavities Family tools. |

Our materials

Available materials

| PVC, POM, PA 6, PA 6.6, PPO, PBT, PPS, |

| LCP, PC, PE, PES, ABS, PP, SAN, |

| PMMA, PS, PET, PC, TPU, TPE |

Briefly explained

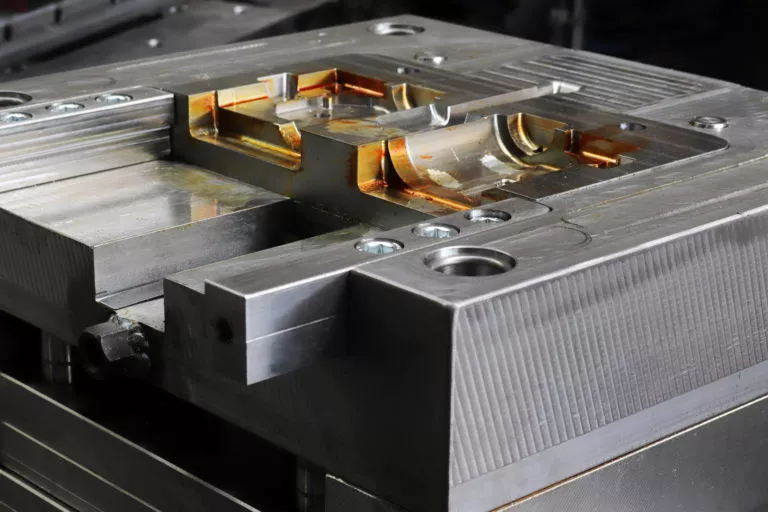

How does injection molding work?

First, the raw material, consisting of plastic granules or powder, is liquefied by heating. The liquid plastic is then injected under high pressure into the molding tool, also called a cavity. After the melt has hardened in the mold, it is opened and the finished plastic part can be removed. The finished parts can then be further refined; common processes include polishing, painting, electroplating and laser marking.

Why Robtrix

Your advantages

- Flexible and free capacities at any time

- Attractive prices for all components

- Quality control according to ISO 9001:2015

- One contract and contact person for all manufacturing processes

- Digital processes with personal contact person

- Global Supply Chain with German Quality Standards 🇩🇪

You have the choice

Our delivery times

- Offer within 48 hours

- Standard production in 15-20 working days

- Express service in 6-12 working days

Surface treatment

We get the best out of your components

Refinement, appearance, protection against wear and corrosion prophylaxis of the turned components are as much part of our core business as the production of components.

- ✔ Sandblasting

- ✔ Paint

- ✔ Anodizing

- ✔ Powder coating

- ✔ Electroless nickel

- ✔ Galvanizing

- ✔ Passivate

- ✔ Chromate