CNC Milling

CNC milled parts with the highest quality simply order online. Attractive prices and fast service incl. Proof of testing with every order. Upload CAD file and receive quote within 48 hours

1.500+

Satisfied customers

5.500+

Available machines

0,11%

Complaint rate

Audited suppliers

Global network with over 500 audited suppliers

Attractive prices

Highest quality and competitive prices for all manufacturing processes

Fast delivery

With Robtrix you reduce your delivery time by up to 50%

Wide range of materials

All plastics and metals available in over 600 materials

Milled parts with on-demand delivery

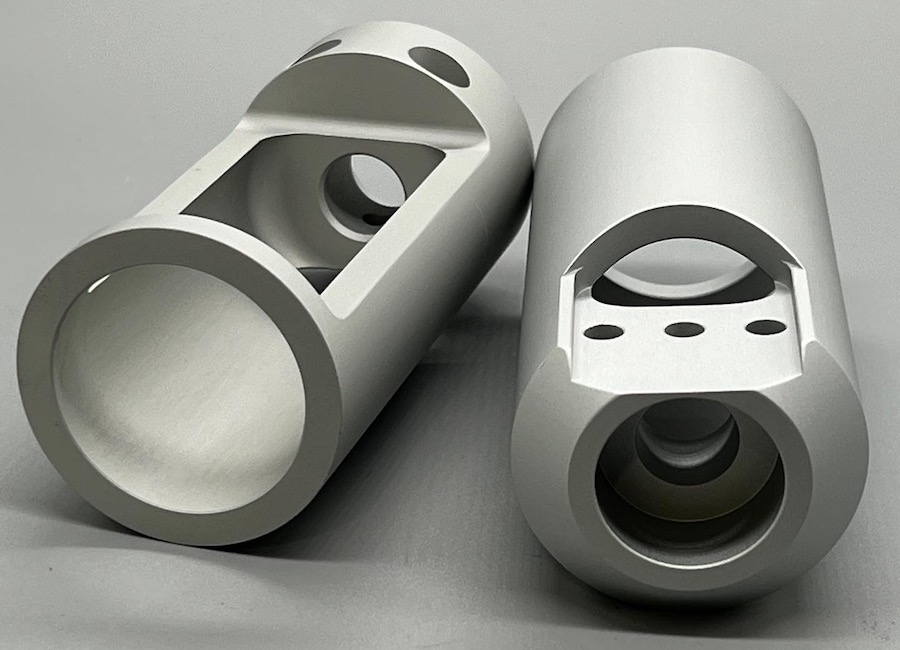

CNC milling of plastic and metal components

Robtrix means simple procurement processes, on-time delivery and compliance with the highest quality standards. Your milled parts are produced on state-of-the-art 3-axis and 5-axis milling machines.

There are hardly any limits to the choice of materials. Robtrix processes all common materials such as aluminum, (stainless) steel and plastic.

Precise manufacturing of prototypes, spare parts or production in series – thanks to the latest machines and processes in CNC milling, we deliver precise components on-demand at the desired delivery date.

CNC Milling

Technical data

| Traverse paths: | X-axis: up to 10,000 mm Y-axis: up to 4,300 mm Z-axis: up to 1,250 mm |

| Tolerances: | from +/- 0.005 mm |

| Surface roughness: | Ra 0.8 – Rz3.2 |

| Batch sizes: | from 1 piece |

| Machines | Modern 3- and 5-axis milling machines |

Our materials

Available materials

| Aluminum | Ceramics |

| Bronze | Plastics |

| Stainless steel | Copper |

| Steel | Brass |

| Casting | Titanium |

| Hard fabric | other materials on request |

| Inconel |

Briefly explained

How does CNC milling work?

Milling is a subtractive manufacturing process. Unlike turning, however, here the tool moves into the clamped material at a higher speed and with a specified feed rate.

Step by step, modern CNC milling machines chip substance from the block, plate or bar material using various cutting tools – known as milling heads – until the workpiece takes on the desired shape.

Shapes and tolerances are defined by an individually created NC program and implemented on the workpiece by the CNC machine. Robtrix usually machines the prepared semi-finished product with 3-axis or 5-axis milling machines.

Robtrix’s high level of manufacturing expertise not only reduces machining and setup times, but also increases the precision of CNC milling. Above all, however, it increases throughput times when producing large quantities.

Discover quick answers to your most common CNC milling questions.

Robtrix is equipped to handle a range of order sizes, from single pieces to high volume production, with ideal lot sizes ranging from 1 to 50,000 pieces. Standard lead times are 15 to 20 business days, with express options available for 6 to 12 business days.

Robtrix’s In general, the size limitation depends on the capacity of the machine, with modern CNC machines capable of milling very small to large parts. For exact size limitations, it’s advisable to consult with Robtrix.

Robtrix supports all the most commonly supported formats in the industry including STL, STEP, IGES, and DXF as well 3D data, PDF, ZIP, XLS, CSV. For specific information, please contact us.

Robtrix offers a range of services and options for CNC machined parts. For detailed information about our post-processing capabilities, we recommend contacting us directly for accurate and complete assistance.

Robtrix takes IP protection and data security very seriously. We use a secure system with end-to-end AES-256 encryption and strict access restrictions. All data is stored on Amazon AWS servers in Germany, and any data shared with partners is anonymized to protect customer intellectual property and confidentiality.

Why Robtrix

Your advantages

- Flexible and free capacities at any time

- Attractive prices for all components

- Quality control according to ISO 9001:2015

- One contract and contact person for all manufacturing processes

- Digital processes with personal contact person

- Global Supply Chain with German Quality Standards 🇩🇪

You have the choice

Our delivery times

- Offer within 48 hours

- Standard production in 15-20 working days

- Express service in 6-12 working days

Surface treatment

We get the best out of your components

Refinement, appearance, protection against wear and corrosion prophylaxis of the turned components are as much part of our core business as the production of components.

- ✔ Sandblasting

- ✔ Paint

- ✔ Anodizing

- ✔ Powder coating

- ✔ Electroless nickel

- ✔ Galvanizing

- ✔ Passivate

- ✔ Chromate